CellSPY for

All Battery Types

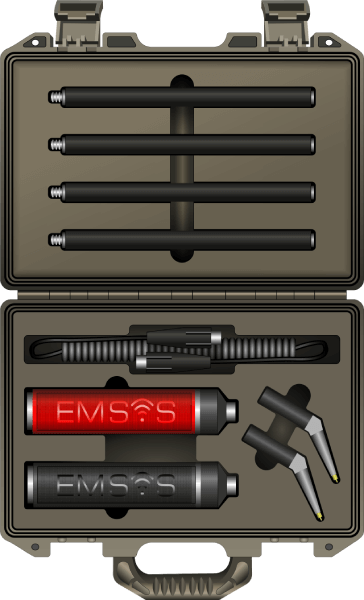

CellSPY Battery Monitor measures Voltage, Temperature, Resistance, & AC Ripple Voltage.

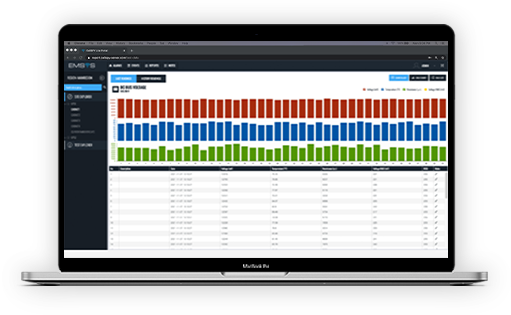

We build complete solutions.

That means from the sensors to the gateways to the cloud to the app running on your desktop or mobile device. We have you covered.

CellSPY Battery Monitor measures Voltage, Temperature, Resistance, & AC Ripple Voltage.

All the features of CellSPY with added Electrolyte Level Monitoring. No Field Calibration & NERC compliant for VLA Batteries.

CellSPY Battery Monitor with no cables. Designed for retrofits where batteries don’t have tab washers.

Designed for IEEE maintenance testing

Designed for IEEE battery capacity testing

Our intuitive software makes transitioning to EMSYS products a breeze. To schedule a demo, fill out the contact form below, and one of our sales engineers will reach out to walk you through our demo system.

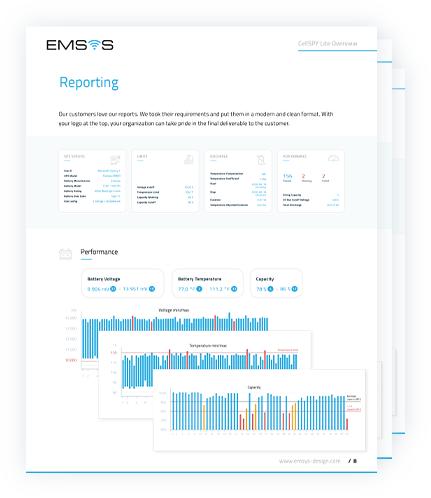

From simple PDFs to powerful HTML based reports, our reporting tools allow you to minimize time spent analyzing data. Identify anomalies quickly & take corrective action.